-

Oilless Bushes

-

Wrapped Bronze Bearings

-

Graphite Plugged Bushings

-

Bronze Sleeve Bushings

-

Self Lubricating Plain Bearing

-

Bronze Gleitlager

-

Polymer Plain Bearings

-

Bimetal Bearing Bushes

-

Bronze Plain Bearings

-

Plastic Plain Bearings

-

Self Lube Wear Plates

-

Stainless Steel Bushings

-

Cast Bronze Bushings

-

Bronze Bushing Material

-

Valve Bushing

-

Self Lubricating Bronze Bushings

-

Flanged Sleeve Bearing

-

Dry Sliding Bearing

-

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality.

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality. -

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts -

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

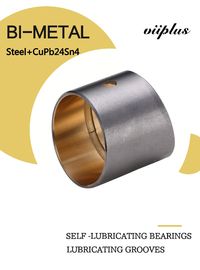

SAE799 Bimetal Bearing Bushes Sintered CuPb24Sn4 Material JF -720 Plain Bearing

| Place of Origin | Bimetal Bearing Manufacturers |

|---|---|

| Brand Name | bimetal SAE-797 SAE 48 SAE-799 bushings |

| Certification | Bimetal Bush Material CuPb10Sn10、CuPb6Sn6Zn3 CuPb24Sn4... |

| Model Number | JF800 JF720 JF700 Bimetal Lead-Free Plain Bearings |

| Minimum Order Quantity | 800 Piece/Pieces (Min. Order) |

| Price | $0.20 - $2.00 / Pieces ,Negotiable |

| Packaging Details | export & import bimetal bushings International carton standard |

| Delivery Time | Manufacture Bimetal Bushing In Stock, Delivered Within Days. |

| Payment Terms | TT IN ADVANCE Western Union |

| Supply Ability | casting bimetal bushing, China, manufacturers, suppliers, factory, wholesale, Metric Self Lubricating Bushing, Self Lubricating Bushings, Journal Bronze Bearings, Bimetal With Graphite Bearing, Metallic Bearings, Flanged Bimetallic Plain Bearing |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Meterial | Bimetal Bushing Material CuPb24Sn4, SAE-799 Bronze Alloy Bearings,CuPb24Sn4 Bimetal Jf720 | Characteristic | Low-maintenance And Maintenance-free Plain Bearings |

|---|---|---|---|

| Size | Standard Size Available | Type | Sleeve, Flanged, Plate, Washers, Strips |

| Bearing | Bi-metal Bushing Steel Backed | Bushing Sample | Available |

| Application | Connecting Rod Level Of Gas Engine, Etc | Feature | Metal Split,Long Life, Dry, Low Resistance, Maintenance Free, Harden |

| Bearing Bushing Factory Price | Tiffany@viiplus.com | Self-lubricating Bearing Bushing Manufacturer | Https://www.viiplus.com/ |

| High Light | Steel Backed Bronze Bushing, Bimetallic Bushes | Bimetallic Bearing Bushing | Bimetal Bearing With Steel Backing And Bronze Overlay • Particularly Suitable For High ... Bimetal Plain Bearings To Standard SAE 792 |

| Bush Bearings Manufacturers Suppliers Exporters | Plain Bearings. Long, Maintenance-free Service, Manufactures Bushings In Various Designs And From Different Materials. Tiffany@viiplus.com, Bushings - Configure And Purchase - Https://www.viiplus.com/ | ||

| High Light | bimetal bush,bimetal bearings |

||

SAE799 Bimetal Bearing Bushes made of Sintered CuPb24Sn4 Material, JF-720 Plain Bearing refers to a type of bearing bushing that is constructed from a bimetal material, specifically a sintered copper alloy containing 24% lead (Pb) and 4% tin (Sn). The SAE799 standard designates certain requirements and specifications for this type of bimetal bearing.

JF-720 is a plain bearing designation, indicating that this bushing is a non-lubricated, low-friction component designed to support radial or axial loads. The sintered CuPb24Sn4 material provides excellent wear resistance, fatigue strength, and conformability, making it suitable for a wide range of applications.

Bimetal bearings are often used in automotive, industrial, and other applications where there is a need for high load capacity, good wear resistance, and low maintenance. The combination of copper, lead, and tin in the sintered alloy results in a material that is both strong and ductile, allowing it to conform to mating surfaces and distribute loads evenly.

When selecting SAE799 bimetal bearing bushes for a specific application, it is important to consider the required dimensions, tolerances, and operating conditions to ensure that the bushings will perform as expected. Additionally, proper installation and maintenance procedures should be followed to maximize the service life of the bearings.

OEM Customized Leaf Spring Bushing Bimetal Bushing Bearing Car Bushes, Steel Backed Plain Bronze, China Supply Factory

Precision Bimetal Bushing manufacturer,DIN-G-CuPb24Sn4 / Steel Bronze Bimetal bushing & strips and prefessional plain bearings supplier,Sintered SAE799 Layer + Steel Backing + Copper Plating / Tin-Plating, Material CuPb24Sn4, SAE-799 Bimetal Bronze Alloy Bearings china maunfacturer.

The sleeve steel bronze bushings & bearings 720 made to order from china are bimetal sliding bearings with a steel strip and sintered CuPb24Sn4 as the surface sliding layer. Thanks to their high performance characteristics, long service lives at low material fatigue and high levels of load capacity, they are suitable for medium speeds and loads. The bushes-720 sliding bearings are used in the construction and agricultural machinery industries.

Bimetal Sleeve Bushings Consists of a high quality low carbon steel backing carring a sintered tin-lead-bronze alloy (CuSn4Pb24) as a sliding layer. In order to improve tribological behavior the sliding layer can be machined with lubricating grooves for oil- or grease storage and distribution. In case of corrosive environment the backing can be copper plated. BIMETAL sleeve Bushings is used for wrapped bushes, thrust washers and bushes in connecting rods of gas engines, etc.

-

Sliding layer can be machined with lubricating grooves and/or with grease indents

-

steel backing can be copper plated

-

Steel+CuPb24Sn4

![]()

It is backed with high quality low carbon steel with tin-lead-bronze alloy (CuSn4Pb24) sintered on its surface.To effectively decrease abrasion, its alloy surface can be machined with oil grooves for easier oil storage. When necessary, an erosion protection coating can be plated on the steel back. In common use, BIMETAL BUSHINGS is made to wrapped bushes,thrust washer and bushes on connecting rod level of gas engine, etc

JF720 Bi-METAL Steel backing with CuPb24Sn4 liner, with good fatigue strength and sliding performance. Primarily applied to fully lubricated connecting rod or main bushings in engines and compressors.Bimetal Bearing & Bushing (SAE799, CuPb24Sn4 material JF-720)

The 720 Bimetal sleeve bushings are bimetal sliding bearings with a steel strip and sintered CuPb24Sn4 as the surface sliding layer.

Visit our online www.bronzegleitlager.com to view more bushing types. These studies highlightactual challenges, from a variety of industries, solved with china ViiPLUS.

|

SURFACE MATERIAL |

LOAD CAPACITY |

RESISTANCE ALLOY RANGE |

TEMPERATURE LIMIT |

|

|---|---|---|---|---|

|

CuPb24Sn4 |

38 N/mm2 |

HB45 |

HB70 |

+170°C |

Bimetal bushings high performance characteristics, long service lives at low material fatigue and high levels of resilience, they are suitable for medium speeds and loads. The 720 steel bronze sleeve sliding bearings are used in the construction and agricultural machinery industries.

Bimetal boundary lubricated rolling bearing is a key component of heavy equipment.VIIPLUS from China is located in jiashan county, zhejiang province, which is the national production base of self-lubricating bearing, bimetal boundary lubrication rolling bearing.With the recovery of the construction machinery industry, the demand from this industry increases sharply, which directly leads to the increase of the demand for self-lubricating bimetal bearings & bushings.The U.S. 's GGB, sankyo oilless and DAIDO are the world's top three makers of self-lubricated bearings, with strong positions in aerospace, automotive and transportation.VIIPLUS also established itself as an industry leader in self-lubricating bearings exported from China.

It is the main product, it has excellent mechanical bearing capacity, especially suitable for the working conditions of non-refueling and non-refueling.In addition, it has low maintenance costs and is corrosion resistant, so it is often installed in large quantities in key parts of tracked heavy equipment.

Bimetal Bearing & Bushing Materiai

Steel+CuPb24Sn

Typicai applicaton

Application: High speed, heavy load engine main shaft and ransmission gearbox, etc.

Metal and Bimetal Bearings JF720

|

Performance |

Data |

|

|

Max dynamic Load P |

|

120N/mm² |

|

Max line speed V |

Greaes lubrication |

2.5m/s |

|

Max PV value |

Greaes lubrication |

2.8N/mm²·m/s |

|

Friction coef μ |

Greaes lubrication |

0.05~0.15 |

|

Max line speed V |

Oil lubrication |

10m/s |

|

Max PV value |

Oil lubrication |

10N/mm²· m/s |

|

Friction coef μ |

Oil lubrication |

0.04~0.12 |

|

Max Working temperature |

Greaes lubrication |

150℃ |

|

Performance |

Data |

|

|

Max Working temperature |

Oil lubrication |

250℃ |

|

Mating Axis |

Hardness |

≥45HB |

|

Mating Axis |

Roughness |

Ra=0.16~0.63 |

|

Alloy layer hardness |

40~60 |

|

|

Thermal conductivity |

60W/(m·k) |

|

|

Coefficient of linear expansion |

19×10-6K-1 |

|

|

We can also develop according to customers special request while out of this table. |

||

Standard Tolerance Dimension Table

|

d

|

D

|

相配轴径

公差( h8)

|

相配座孔

公差(H7)

|

压入H7座孔

内径公差

|

Wall thickness

壁厚

|

注油孔

|

f1

|

f2

|

L 0

-0.40 |

||||||||

|

min

|

max

|

10

|

15

|

20

|

25

|

30

|

40

|

50

|

60

|

||||||||

|

10

|

12

|

10-0.022

|

12+0.018

|

+0.148

+0.010 |

0.995

|

0.935

|

4

|

0.5

|

0.3

|

1010

|

1015

|

1020

|

|

|

|

|

|

|

12

|

14

|

12-0.027

|

14+0.018

|

1210

|

1215

|

1220

|

|

|

|

|

|

||||||

|

14

|

16

|

14-0.027

|

16+0.018

|

1410

|

1415

|

1420

|

|

|

|

|

|

||||||

|

15

|

17

|

15-0.027

|

17+0.018

|

1510

|

1515

|

1520

|

|

|

|

|

|

||||||

|

16

|

18

|

16-0.027

|

18+0.018

|

0.8

|

0.4

|

1610

|

1615

|

1620

|

|

|

|

|

|

||||

|

18

|

20

|

18-0.027

|

20+0.021

|

+0.151

+0.010 |

1810

|

1815

|

1820

|

1820

|

|

|

|

|

|||||

|

20

|

23

|

20-0.033

|

23+0.021

|

+0.181

+0.020 |

1.490

|

1.430

|

2010

|

2015

|

2020

|

2020

|

|

|

|

|

|||

|

22

|

25

|

22-0.033

|

25+0.021

|

6

|

2210

|

2215

|

2220

|

2220

|

|

|

|

|

|||||

|

24

|

27

|

24-0.033

|

27+0.021

|

1.0

|

0.5

|

2410

|

2415

|

2420

|

2420

|

2430

|

|

|

|

||||

|

25

|

28

|

25-0.033

|

28+0.021

|

|

2515

|

2520

|

2520

|

2530

|

|

|

|

||||||

|

26

|

30

|

26-0.033

|

30+0.021

|

+0.205

+0.030 |

1.980

|

1.920

|

|

2615

|

2620

|

2620

|

2630

|

|

|

|

|||

|

28

|

32

|

28-0.033

|

32+0.025

|

|

2815

|

2820

|

2820

|

2830

|

2840

|

|

|

||||||

|

30

|

34

|

30-0.033

|

34+0.025

|

1.2

|

0.6

|

|

3015

|

3020

|

3020

|

3030

|

3040

|

|

|

||||

|

32

|

36

|

32-0.039

|

36+0.025

|

|

3215

|

3220

|

3220

|

3230

|

3240

|

|

|

||||||

|

35

|

39

|

35-0.039

|

39+0.025

|

|

|

3520

|

3520

|

3530

|

3540

|

3550

|

|

||||||

|

38

|

42

|

38-0.039

|

42+0.025

|

8

|

|

|

3820

|

3820

|

3830

|

3840

|

3850

|

|

|||||

|

40

|

44

|

40-0.039

|

44+0.025

|

|

|

4020

|

4020

|

4030

|

4040

|

4050

|

|

||||||

|

d

|

D

|

相配轴径公差(h8)

|

相配座孔公差(H7)

|

压入H7座孔内径公差

|

Wall thickness

壁厚

|

注油孔

|

f1

|

f2

|

L 0

-0.40 |

||||||||

|

min

|

max

|

25

|

30

|

40

|

50

|

60

|

80

|

90

|

100

|

||||||||

|

45

|

50

|

45-0.039

|

50+0.025

|

+0.205

+0.030 |

2.460

|

2.400 |

8

|

1.5

|

1.0

|

4525

|

4530

|

4540

|

4550

|

|

|

|

|

|

50

|

55

|

50-0.039

|

55+0.030

|

+0.210

+0.030 |

|

5030

|

5040

|

5050

|

5060

|

|

|

|

|||||

|

55

|

60

|

55-0.046

|

60+0.030

|

|

5530

|

5540

|

5550

|

5560

|

|

|

|

||||||

|

60

|

65

|

60-0.046

|

65+0.030

|

|

6030

|

6040

|

6050

|

6060

|

|

|

|

||||||

|

65

|

70

|

65-0.046

|

70+0.030

|

|

6530

|

6540

|

6550

|

6560

|

|

|

|

||||||

|

70

|

75

|

70-0.046

|

75+0.030

|

|

7030

|

7040

|

7050

|

7060

|

7080

|

|

|

||||||

|

75

|

80

|

75-0.046

|

80+0.030

|

9.5

|

|

7530

|

7540

|

7550

|

7560

|

|

|

|

|||||

|

80

|

85

|

80-0.046

|

85+0.035

|

+0.215

+0.030 |

|

|

8040

|

8050

|

8060

|

8080

|

|

|

|||||

|

85

|

90

|

85-0.054

|

90+0.035

|

|

8530

|

|

8550

|

8560

|

8580

|

|

85100

|

||||||

|

90

|

95

|

90-0.054

|

95+0.035

|

|

|

|

9050

|

9060

|

9080

|

|

90100

|

||||||

|

95

|

100

|

95-0.054

|

100+0.035

|

|

|

|

|

9060

|

9080

|

9090

|

90100

|

||||||

|

100

|

105

|

100-0.054

|

105+0.035

|

|

|

|

|

10060

|

10080

|

10090

|

100100

|

||||||

|

105

|

110

|

105-0.054

|

110+0.035

|

|

|

|

|

10560

|

10580

|

|

105100

|

||||||

|

110

|

115

|

110-0.054

|

115+0.035

|

|

|

|

|

11060

|

11080

|

|

110100

|

||||||

|

115

|

120

|

115-0.054

|

120+0.035

|

|

|

|

11550

|

|

11580

|

|

|

||||||

|

120

|

125

|

120-0.054

|

125+0.040

|

+0.220

+0.030 |

|

|

|

12050

|

12060

|

|

|

120100

|

|||||

|

125

|

130

|

125-0.063

|

130+0.040

|

|

|

|

|

|

|

|

125100

|

||||||

|

130

|

135

|

130-0.063

|

135+0.040

|

|

|

|

|

13060

|

|

|

130100

|

||||||

|

135

|

140

|

135-0.063

|

140+0.040

|

|

|

|

|

13560

|

13580

|

|

|

||||||

|

140

|

145

|

140-0.063

|

145+0.040

|

|

|

|

|

14060

|

14080

|

|

140100

|

||||||

|

150

|

155

|

150-0.063

|

155+0.040

|

|

|

|

|

15060

|

15080

|

|

150100

|

||||||

Jf-720 CuPb24Sn Bimetal Metal Bushing

Jf-720 bimetallic bearing is a product of CuPb24Sn4 alloy sintered on the surface of steel plate.The product has good fatigue strength and bearing capacity.Suitable for medium speed, medium load and oil lubrication.When the surface is plated with soft alloy, it can be used as the bearing and connecting rod bushing of high-speed internal combustion engine to achieve good wear resistance and fatigue resistance.

Because the matrix is stable as low carbon steel material, so the machining accuracy of the outer diameter of the shaft sleeve has been guaranteed, and there is no need for screw fixation after the product is loaded into the seat hole, relying on interference fit can prevent the phenomenon of going out of the circle.The change of chemical composition of inner surface alloy layer can meet the requirements of different bearing pressure, different service temperature and different sliding speed. The oil groove and oil hole with different structure are designed in the production of friction surface to meet the requirements of different ways of oil adding, prevent shaft biting and adapt to different lubrication conditions.

Widely used in automobile engine, motorcycle clutch, light industrial machinery, construction machinery.

Alloy layer material CuPb10Sn10 or CuSn6Zn6Pb3

Application

Bimetal bearing is widely used in automotive applications such as compressors, steering gear, power steering, pedal bearings, king-pin bushes, tailgate pivots, mechanical handling and lifting equipment, hydraulic motors, agricultural machinery etc.

Standard Bimetal Parts Available

1. Cylindrical bush with split or with clinched joint.

2. Flanged bush with split or with clinched joint.

3. Thrust washers.

4. Strips

Customized Bushings

We are professional in developing and produce customized bimetal bushings

1. Cylindrical bush with split or with clinched joint.

2. Flanged bush with split or with clinched joint.

3. Thrust washers.

4. Strips

Typical Characteristics

Suitable for low speed, heavy load or intermittent movement conditions, lubricating oil film can not form or maintain the occasion;

Suitable for working environment or mechanical structure restrictions, it is difficult to supply oil lubrication occasions;

It is suitable for rotating, reciprocating, swinging, linear and other forms of movement, as well as occasions requiring frequent starting or starting under high load;

Suitable for high or low temperature work, or the environment temperature range of large occasions;Good corrosion resistance, can be used in seawater and other corrosive media such as chemical liquids or gases, as well as water containing sediment or radioactive environment;

Non-water absorption, good dimensional stability, high mechanical strength, good thermal conductivity;

Bearing is thin wall structure, light weight, small volume, suitable for compact design;

Compared with the traditional three-layer composite material, the static load characteristics, wear-resistance, service temperature, dimensional stability and so on under the condition of non-grease lubrication are better;

Compared with copper inlaid self-lubricating material, it is more suitable to work under the condition of small Angle swing, and the price is cheaper.

Range Of Application

The products are applied to water conservancy and hydropower industry: hydraulic machinery: horizontal support slide of hydraulic steel gate, support bearing of hydraulic hoist and closure machine, sand blasting maintenance door bearing, etc.Hydraulic turbine: guide vane shaft sleeve (upper guide, middle guide, lower guide), wheel shaft sleeve, pin shaft sleeve (connecting rod pin, push and pull rod pin, relay piston pin), anti-wear ring plate (thrust ring), anti-wear block, control ring side tile.

Metallurgical industry: die-casting machine bearing, rolling cutting shears (bilateral shears, fixed length shears on the skateboard), etc.Valve industry: butterfly valve, globe valve, etc.Others: mining machinery, packaging machinery, construction machinery, heavy machinery, injection molding machine, automobile tire mold, wind turbine, thermal power and other industries.

This product is the most powerful bearing capacity in the double-alloy bearing, the balance bridge bushing and gasket of heavy vehicles;Driven wheel and supporting wheel of bulldozer;Automobile steel plate bushing, USES this product.It is a kind of high load and low speed sliding bearing widely used.

Agricultural Machinery

As the self-lubricating bearing has the characteristics of maintenance-free and good abrasion resistance under dust and outdoor conditions, it is widely used in the cylinder, suspension system of combine harvester, planter, baler, crusher, tractor, Joints and other parts can not be difficult to form oil or oil film parts.

![]()

-

Fork lifts

-

Pallet Trucks

-

Cranes

-

Excavators

Properties

-

For high load capacity and oscillating movement, as well as for rough operation and temperature load. Long-run lubrication because of lubricant storage.

Tolerance Details

-

Housing ØH7

-

Bushing inner-Ø after mountingH9

-

Shaft tolerancef7 to h8

Maintenance

-

is a low-maintenance composite sliding bearing, but primary lubrication is necessary. Oil or grease lubrication is possible. Due to solid lubricant storages, lubrication clearances are reduced to a minimum!

CAPTION:Special dimensions are available on request

Get in touch ...Send us an online enquiry

You can use our “Enquiry Form” to get in touch with us. One of our sales team will contact you immediately.

![]()